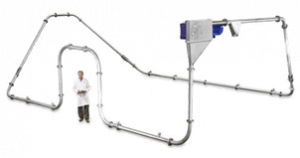

When you need to move a variety of materials in all directions our tubular drag conveyors allow for the reliable transport of material across long or short distances. Our tubular drag conveyors can be setup to process across multiple levels, and can be custom designed to meet your unique layout configuration needs. We only supply the best performance chain conveyor.

• Convey product in a completely sealed system. The sprocket drive pulls a heavy-duty chain and flight assembly through a fully enclosed casing, moving material through the pipe. This conveying method won’t separate or degrade the product and prevents dusting.

• Use less energy than other conveyors. Low horsepower comes from our unique tubular drag conveyor design, which produces the steady drag that cuts your unit energy costs by our drag chain conveyors

• Move challenging materials. Convey high-moisture ingredients, abrasive, blended, friable, easy-to-compact, large particle, or smear products without compromising quality.

• One conveyor does the work of many. Configure the tubular drag conveyor to convey product vertically, horizontally, at any angle, and around corners. Inlets and outlets can be configured where needed. Many layouts are available.

• Our Patented Chain conveyors. High torque, low-speed design with the ability to start and stop while fully loaded! The tubular cable conveyor must be started empty.

• Self-Cleaning Discharge Gate: Prevent material from getting trapped with this exclusive discharge gate design. The gate opens and closes flat against the convex pipe, eliminating trapped material.

• Brush Box: Effectively remove sticky material from flights and chains with dual spinning brushes that prevent carryover, and facilitate full material discharge from the conveyor. Other cleaning options are available, such as an air knife and vibration box.

• Auto Tensioner: Patented air-over-hydraulic auto tensioner mitigates unplanned downtime and dramatically reduces maintenance. Built-in sensors automatically keep the chain at optimum performance, even under varying loads.

• Flight and Chain Configurations: Our engineers will select the correct chain and flight design combination to meet your specific process and material requirements. We offer link and pin-type chains conveyors, which are less prone to fatigue and wear, and stretch less than steel cables. Also available are Hapman’s exclusive rivetless and seal-pin chain options to fit a wider array of applications.