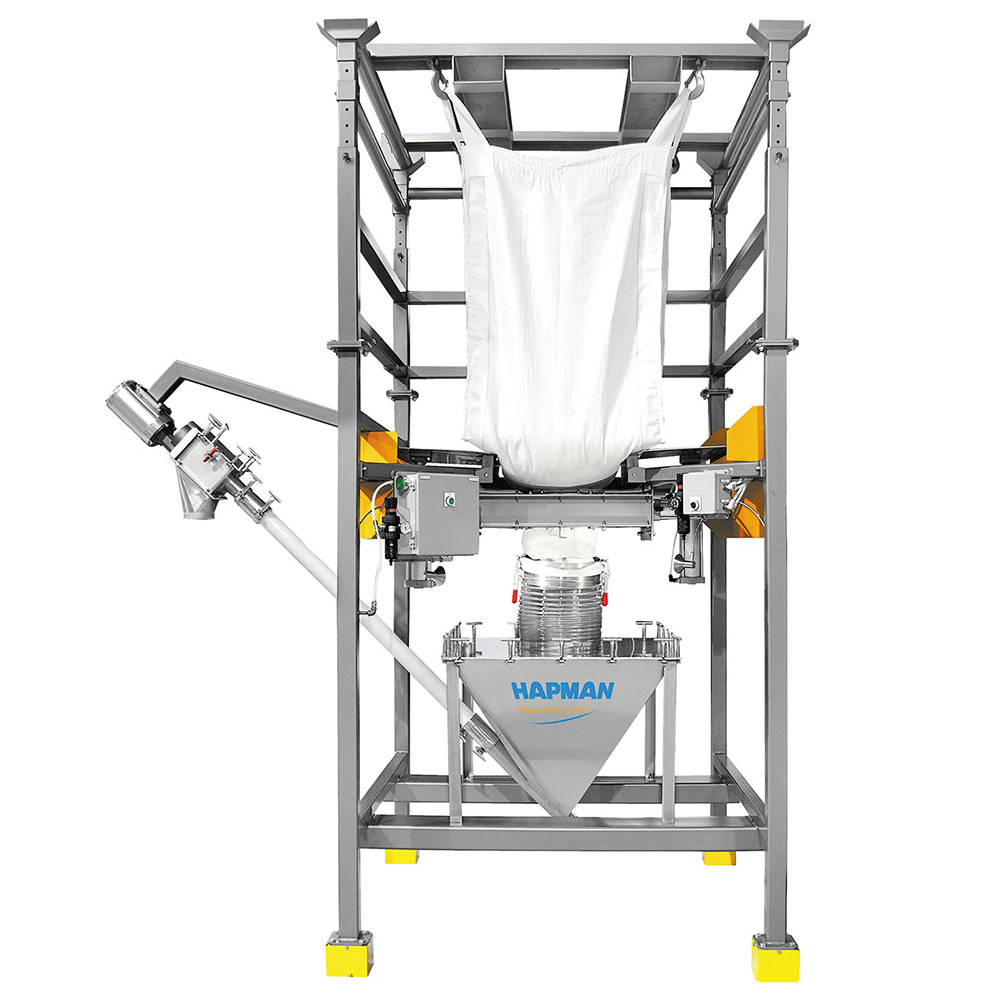

Bulk Bag Unloaders

Our bulk bag unloaders are designed to safely and effectively unload large bags of material. No matter your needs, regulations, or materials, we can provide a system that will quickly and efficiently allow for processing material from bulk bags and into your system.

• Unloads bags easily and safely.

• Assures smooth discharge of your products with a complete range of flow aid options.

• Installs quickly with a two-piece frame, or fits in tight spaces with the low-profile frame.

• Eliminates product loss through spillage and dusting

• Ability to start/stop the flow with discharge valve and tie box.

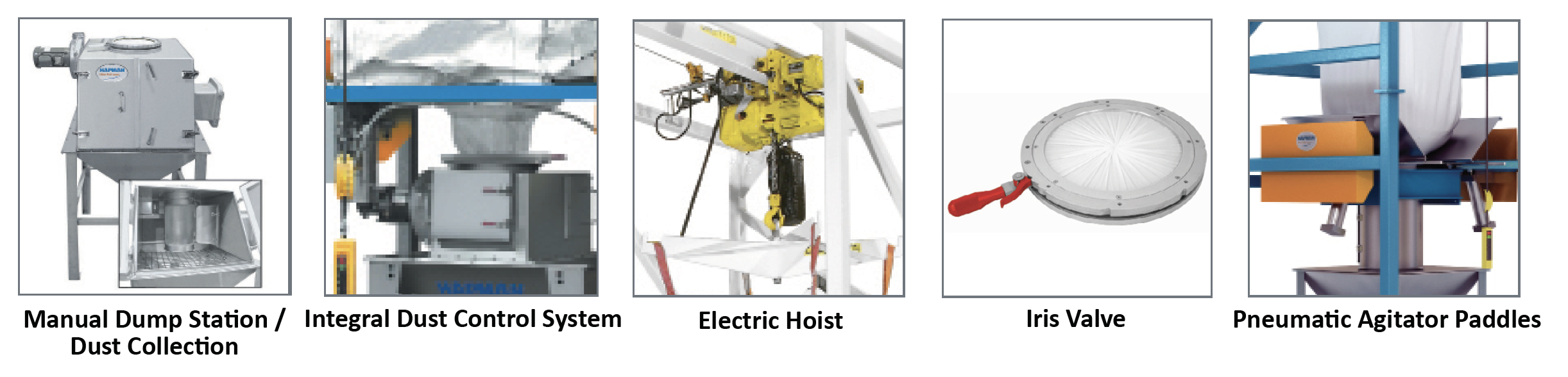

• Self-Contained Dust Control System: These units eliminate dust and loss of product in half the space of stand-alone units and cost 25% less.

• Hoists: Suit any application with optional pneumatic and electric hoists when using hoist and trolley style frame.

• Valves: Get more precise flow control with optional iris or pinch valves. Even retie bags when necessary.

• Material Discharge Optimization: Improve material discharge with optional pan utilizing rubber vibration dampers and electric vibrator (not shown).

• Customized Engineered Designs: Fit tight spaces with a custom-designed frame when you need to work around or straddle another piece of equipment or obstruction.

• Pneumatic Agitator Paddles: Ideal for use with material that is easily compacted or difficult-to-dispense, agitator paddles mitigate bridging and rat holes.

• Hydraulic Bag Conditioners: Designed to break up bags of hardened material (not shown).